Tribupneu: The Future of Pneumatic Innovation and Motion

Introduction: The Evolution of Smart Motion Systems

In today’s rapidly evolving era of automation and mechanical design, industries are driven by the pursuit of efficiency, precision, and sustainability. Every robotic arm, valve, and pneumatic actuator contributes to the heartbeat of modern manufacturing systems. However, the real challenge lies not only in generating power but in how efficiently that power is transferred, controlled, and maintained.

Tribupneu emerges as a groundbreaking concept in this landscape — a fusion of tribology (the science of friction, wear, and lubrication) and pneumatics (the science of motion driven by compressed air). It represents more than a product; Tribupneu introduces a transformative technology ecosystem that enhances reliability, energy efficiency, and sustainability in pneumatic motion systems.

What Is Tribupneu?

The term Tribupneu combines two essential branches of mechanical science:

-

Tribology: The study of friction, lubrication, and surface wear between moving parts.

-

Pneumatics: The use of compressed air to generate controlled motion.

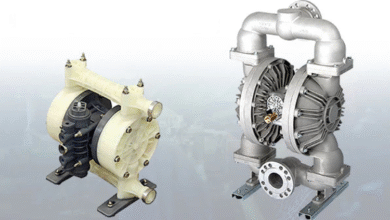

By merging these principles, Tribupneu creates a synergy that results in smoother operations, longer component life, and reduced energy losses. This innovative approach delivers a new class of motion control and lubrication systems specifically tailored for pneumatic devices used across industries like robotics, automation, aerospace, manufacturing, and healthcare.

Unlike traditional pneumatic or lubrication systems, Tribupneu continuously adapts to real-time conditions. It integrates surface science, advanced lubrication technology, and smart air-based actuation — producing superior mechanical performance while minimizing friction and power waste.

How Tribupneu Works: The Science Behind the System

The brilliance of Tribupneu lies in its dual capability to manage both air pressure and surface interaction simultaneously. Its innovation can be understood through several core functions:

1. Friction Reduction and Surface Protection

Advanced tribological coatings and synthetic lubricants form a microscopic protective film on component surfaces. This barrier prevents metal-to-metal contact even under extreme pressure, significantly reducing wear. As a result, pneumatic cylinders, valves, and actuators last much longer and perform consistently.

2. Smart Pneumatic Efficiency

Tribupneu employs integrated pressure sensors and adaptive algorithms that monitor friction and air flow in real time. If resistance or drag increases, the system automatically adjusts air pressure or lubrication delivery to maintain optimal performance.

3. Moisture and Corrosion Control

Moisture intrusion is a common issue in compressed air systems, leading to corrosion and energy inefficiency. Tribupneu uses water-repellent formulations that create a protective barrier, keeping internal components dry and corrosion-free.

4. Seal Protection and Longevity

Rubber and polymer seals, such as nitrile and polyurethane, often degrade under continuous air pressure. Tribupneu protects these seals from swelling, cracking, and shrinking — ensuring longer-lasting, leak-free pneumatic performance.

Key Benefits of Using Tribupneu

The adoption of Tribupneu delivers tangible benefits across multiple engineering and industrial applications:

Extended Equipment Lifespan

By minimizing friction and surface wear, Tribupneu extends the operational lifespan of pneumatic systems by up to three times compared to conventional setups.

Enhanced Energy Efficiency

Reduced resistance and optimized air pressure translate into less compressor workload. This lowers overall energy consumption and reduces operational costs.

Improved Consistency and Accuracy

The stable lubrication and adaptive air flow control offered by Tribupneu ensure smoother, quieter, and more precise motion — crucial for automation and robotic applications.

Reduced Maintenance and Downtime

Lower friction leads to less frequent component replacement, minimizing maintenance costs and equipment downtime.

Eco-Friendly Performance

By using air and advanced eco-safe lubricants instead of hydraulic fluids, Tribupneu supports green engineering initiatives and helps industries achieve sustainability goals.

Applications of Tribupneu Across Industries

1. Robotics and Automation

Tribupneu enables robotic systems to move with natural fluidity and precision. Its adaptive friction control allows robots to maintain consistent movement and energy efficiency, enhancing productivity in automated environments.

2. Automotive Manufacturing

In high-speed production lines, pneumatic actuators powered by Tribupneu perform faster and more reliably. This improves product quality while reducing the risk of system failures.

3. Aerospace Systems

Weight reduction and efficiency are crucial in aerospace. Tribupneu’s intelligent air-based control systems deliver both, providing precision and long-term reliability under demanding conditions.

4. Healthcare and Prosthetics

In medical applications, Tribupneu technology contributes to prosthetic and rehabilitation devices that mimic natural, responsive movement while ensuring comfort and durability.

5. Heavy Industry and Metalworking

From grinders to pneumatic tools, Tribupneu enhances sealing, lubrication, and motion accuracy — ensuring stable performance even in extreme industrial environments.

Smart Integration: Sensors and AI in Tribupneu

Modern Tribupneu systems are intelligent, not static. Equipped with smart sensors and AI-driven controllers, they continuously collect and analyze data related to friction, temperature, and air pressure.

This allows predictive maintenance, where potential issues are identified and resolved before they lead to system failure. By combining real-time monitoring with artificial intelligence, Tribupneu brings a new level of automation and reliability to mechanical systems.

Challenges and Future Outlook

While Tribupneu presents a promising future, a few challenges must be addressed for its widespread adoption:

-

Higher Initial Costs: Advanced materials and intelligent sensors can make initial investment relatively high.

-

Training and Skill Development: Maintenance personnel and engineers require additional training to optimize Tribupneu systems.

-

Standardization Needs: Industry-wide compatibility and performance standards are still evolving.

Despite these hurdles, the potential of Tribupneu in reshaping motion control systems is undeniable. As industries move toward digitalization and sustainability, this technology stands at the forefront of the next industrial transformation.

Conclusion

Tribupneu represents the perfect intersection of science, engineering, and sustainability. By merging tribology and pneumatics, it pioneers a new generation of intelligent, eco-friendly motion control systems.

This evolution doesn’t just make machines perform better — it redefines how industries think about energy, efficiency, and longevity. Through predictive intelligence, self-adjusting mechanisms, and eco-safe designs, Tribupneu symbolizes the future of motion — smarter, cleaner, and more sustainable.

As industries worldwide transition toward digital and green technologies, Tribupneu is set to become an essential part of the next wave of industrial progress. Adopting Tribupneu means more than upgrading a system; it means embracing a future where every movement is efficient, every machine lasts longer, and every operation contributes to a cleaner planet.

FAQs about Tribupneu

1. What makes Tribupneu different from traditional pneumatic systems?

Tribupneu integrates tribological science with pneumatic motion, combining lubrication, air pressure control, and smart sensors to reduce friction and improve efficiency — something traditional systems cannot achieve.

2. Can Tribupneu be used in existing pneumatic systems?

Yes. With proper adaptation, Tribupneu technology can be integrated into most existing pneumatic systems to enhance performance and reduce wear.

3. How does Tribupneu improve sustainability?

By using air and environmentally safe lubricants, Tribupneu eliminates harmful hydraulic fluids and reduces energy waste, supporting sustainable industrial practices.

4. Is Tribupneu cost-effective in the long run?

While the initial investment may be higher, Tribupneu reduces maintenance costs, energy use, and equipment downtime, making it highly cost-effective over time.

5. What industries benefit most from Tribupneu?

Industries such as automation, robotics, manufacturing, aerospace, and healthcare benefit the most due to the system’s efficiency, precision, and longevity.